- Tensile Testing:Tensile testing determines the tensile strength, elongation, and modulus of elasticity of a rubber material.

- Compression Testing:Compression Testing measures how a material behaves under crushing loads and its recovery.

- Hardness Testing:Hardness Testing gauges the material's resistance to indentation.

- Aging Testing:Aging Testing simulates long-term environmental degradation.

- Tear Resistance Testing: Tear Resistance Testing evaluates how well a material resists the growth of nicks or cuts.

- Chemical Resistance Testing: Chemical Resistance Testing assesses performance against oils, fuels, and solvents.

- Compression Set Testing:Compression Set Testing reveals a material's ability to recover after sustained deformation.

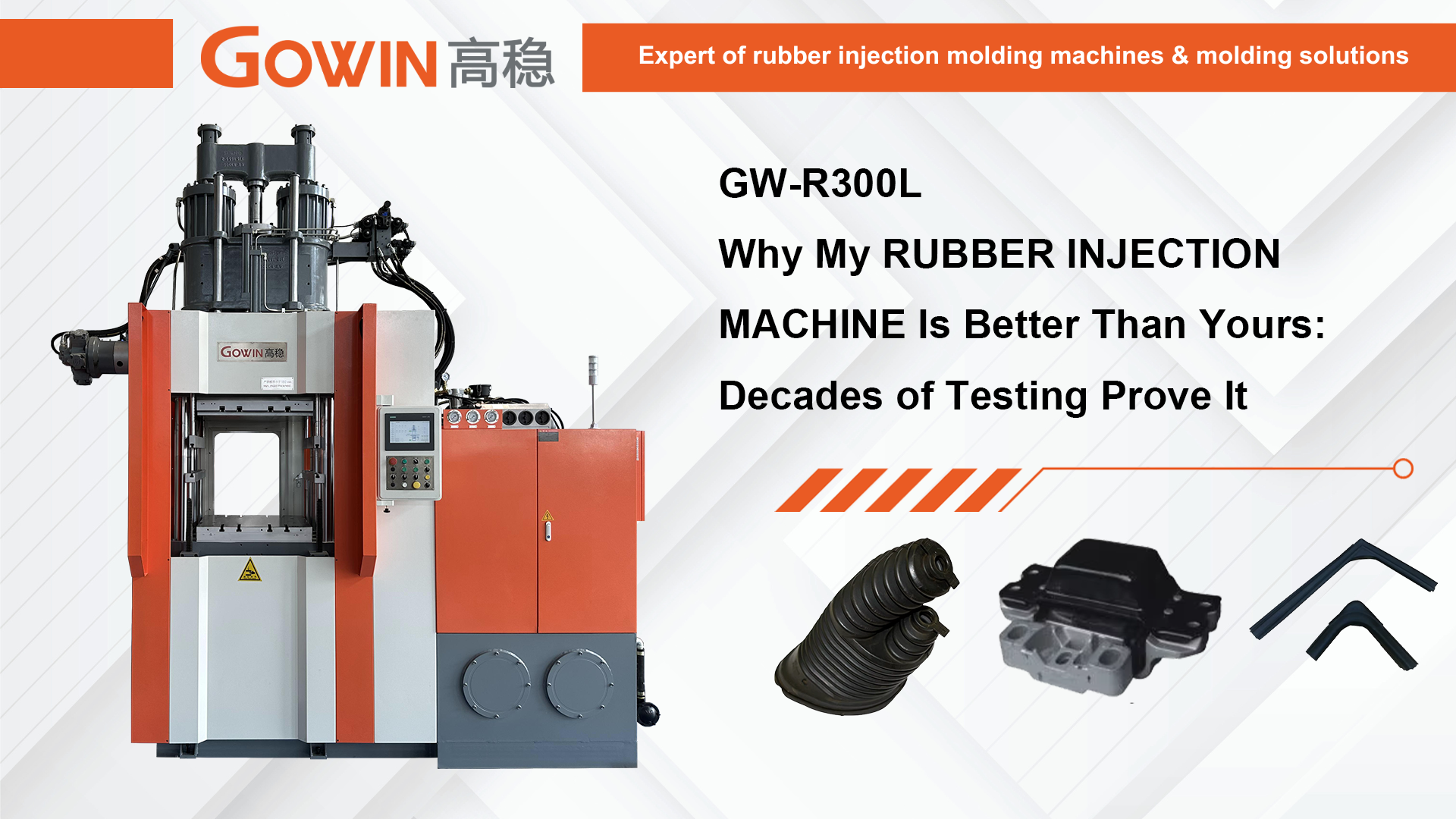

- Rubber Molding and Rubber Material Testing: These are not mere checkboxes; they are the bedrock of predictable, high-performance parts. And after 30+ years crafting narratives for the heart of the rubber manufacturing news cycle, I can tell you this unequivocally: the true measure of a rubber injection moulding machine isn't just its specs sheet, but how intrinsically it enables passing these tests with flying colours, consistently, day in and day out. Mine does. Let me explain why yours probably falls short.

Beyond the Platen: Where Testing Meets Machine Performance

Too many manufacturers focus solely on cycle times and tonnage. Cycle times mean nothing if your parts fail compression set tests after six months in an engine bay. Tonnage is irrelevant if inconsistent cavity pressure leads to variable hardness readings across a single production run. My machines are engineered with a fundamental understanding that every aspect of their operation directly impacts those critical test results downstream.

1. Precision That Dictates Tensile & Elongation: Achieving the exact molecular structure needed for superior tensile strength and elongation starts with unmatched precision in temperature control and injection speed. Slight variations in melt temperature dramatically affect cross-linking density – the very core of tensile properties. My direct-drive, closed-loop servo injection system doesn't just claim precision; it delivers melt consistency shot after shot, ensuring the material entering the mold has the exact thermal history required to hit those tensile specs. Competing machines relying on older hydraulics simply cannot match this thermal stability, leading to batch-to-batch variations that kill your tensile test consistency – and your reputation with rubber moulding manufacturers supplying critical injection molding automotive industry components.

2. The Compression & Compression Set Imperative: Think rubber compression molding machine is the only game for these properties? Think again. Modern high-precision rubber injection moulding machines, like mine, achieve compression properties rivaling traditional compression molding, but with vastly superior efficiency and complex geometry capability. The secret? Unrelenting control over clamp force and injection pressure profiles. Inconsistent clamp force leads to flash, which alters the effective compression geometry of the part during testing. Poor pressure control during injection and cure phases creates internal stresses and incomplete vulcanization – the prime culprits behind catastrophic compression set failure. My machine’s real-time, adaptive pressure control and industry-leading platens parallelism guarantee uniform cavity pressure distribution. This translates directly to parts that compress predictably and recover as specified, batch after batch, crucial for seals in the booming automotive rubber molded components market.

3. Hardness: It's Not Just the Formulation: You spec a 70 Shore A material. Why do parts vary from 68 to 72 across the mold, or worse, shot-to-shot? Inconsistent dispersion of fillers, uneven vulcanization due to temperature gradients within the cavity, or trapped air pockets are often the hidden machine-induced culprits. My machine combats this with:

Ultra-Precise Temperature Zones: Independently controlled, with minimal overshoot/undershoot, ensuring uniform heat transfer across the entire mold surface.

Advanced Screw Design & Mixing: Engineered for homogeneous compound plastication and filler dispersion before injection, eliminating soft spots.

Vacuum Molding Capability (Optional but Critical): Standard on many of my models, it actively removes air and volatiles from the cavity, preventing voids and surface defects that skew hardness readings. Can your standard silicone rubber injection molding machine claim the same level of control over these factors?

4. Conquering Aging, Tear, & Chemical Resistance: The Long Game: These tests expose weaknesses built into the part during molding. Under-cure due to unstable temperature control? Expect poor aging resistance and chemical resistance. Internal voids or stress concentrations from turbulent flow? Kiss tear resistance goodbye. Overcure from excessive temperatures or hold times? Brittleness sets in, failing multiple tests. My machine’s closed-loop control over every thermal parameter (barrel, nozzle, hot runner, platen) and injection profile (speed, pressure, position) ensures exactly the right amount of energy is delivered for exactly the right time. This precision vulcanization is non-negotiable for parts destined for harsh environments – think rubber wire mold products in EV battery packs or seals in chemical processing. It’s the difference between a part that sails through 1000 hours of heat aging and one that cracks at 500.

5. Built for the Grind: Reliability is a Test Parameter Too: The most consistent machine is worthless if it’s down for maintenance every other week. Downtime kills profitability and forces rushed production, inevitably compromising quality and test results. Three decades in this field have taught me where corners are cut. My machines use premium, globally sourced components specifically chosen for endurance in the demanding rubber molding environment. Heavy-duty construction, superior heat management systems, and accessible service points aren't luxuries; they're necessities for maintaining the precision demanded by rigorous Rubber Molding and Rubber Material Testing protocols year after year. This relentless reliability directly translates to stable, predictable production output that meets the just-in-time demands of the automotive rubber molded components market.

Why "CE Certification Rubber Vulcanizing Press Machinery" Isn't Just a Sticker (And Why Mine Excels)

CE certification rubber vulcanizing press machinery is a baseline legal requirement for the EU market, signifying compliance with essential health, safety, and environmental protection directives. But true excellence goes far beyond mere compliance. My machines embody the spirit of CE through:

Inherent Safety by Design: Beyond guarding, think fail-safe hydraulic circuits, thermal overload protection integrated at the system level, and pressure relief systems designed with redundancy. Safety isn't bolted on; it's engineered in. This protects your operators and ensures uninterrupted production.

Energy Efficiency Built-In: CE pushes efficiency; my machines lead it. Regenerative hydraulic systems (where applicable), high-efficiency servo motors, and intelligent thermal management drastically reduce operating costs compared to older, energy-guzzling competitors. This isn't just greenwashing; it's a significant competitive advantage in today's market.

Emissions Control Integration: Designed with optional fume extraction interfaces and compatibility with closed-loop cooling systems, making compliance with increasingly stringent environmental regulations straightforward.

The Competitive Edge: It's in the Results

When you choose my rubber injection moulding machine, you're not just buying metal and hydraulics. You're investing in a system designed from the ground up to be the ultimate enabler of quality. You're buying:

Unmatched Consistency: Reduce scrap, minimize rework, pass audits effortlessly. Hit your tensile, compression set, hardness, and every other spec, every single time.

Material Savings: Precision shot control and minimal scrap (thanks to superior control and optional vacuum) directly improve your bottom line. Efficient plastication reduces compound heat history, preserving material properties.

Speed to Market: Reliability and consistency mean fewer production hiccups and faster qualification of new tools and materials for demanding applications like injection molding automotive industry projects.

Future-Proofing: Designed for adaptability – handle everything from demanding FKM compounds for aerospace to sensitive medical-grade silicone (silicone rubber injection molding machine performance is a particular specialty), to high-volume EPDM for automotive. Ready for automation integration.

Peace of Mind: Backed by deep industry expertise and support grounded in 30+ years, not just a sales manual. We understand the tests you face because we design machines to help you ace them.

The Bottom Line: Don't Gamble Your Reputation on Inferior Equipment

In the high-stakes world of rubber molding, particularly supplying the exacting automotive rubber molded components market or producing mission-critical rubber wire mold products, consistent test performance isn't optional; it's existential. You can have the best compound and mold design, but if your machine introduces variability, instability, or inconsistency, you will fail. You will face costly rejections. You will lose contracts.

My machines are the culmination of three decades of listening, learning, and engineering solutions to the real problems faced on the production floor and in the testing lab. They are built to be the most reliable, precise, and consistent partners in your quest for flawless rubber parts. That's not marketing hyperbole; it's the demonstrable result of a machine philosophy rooted in the fundamental science of Rubber Molding and Rubber Material Testing.

So, when you ask, "Why is my RUBBER INJECTION MACHINE better than yours?" The answer is simple: Because mine is engineered to ensure your parts pass the test. Every test. Every time. Isn't that what truly matters? Let's talk about how my machine can become the foundation of your quality success story.

Post time: Aug-22-2025