The global energy sector is at a crossroads. With renewable energy investments surging and grid modernization projects accelerating, high-performance insulators have become the backbone of safe, efficient power transmission. Yet, traditional manufacturing methods struggle to meet the precision, speed, and sustainability demands of today’s energy landscape.

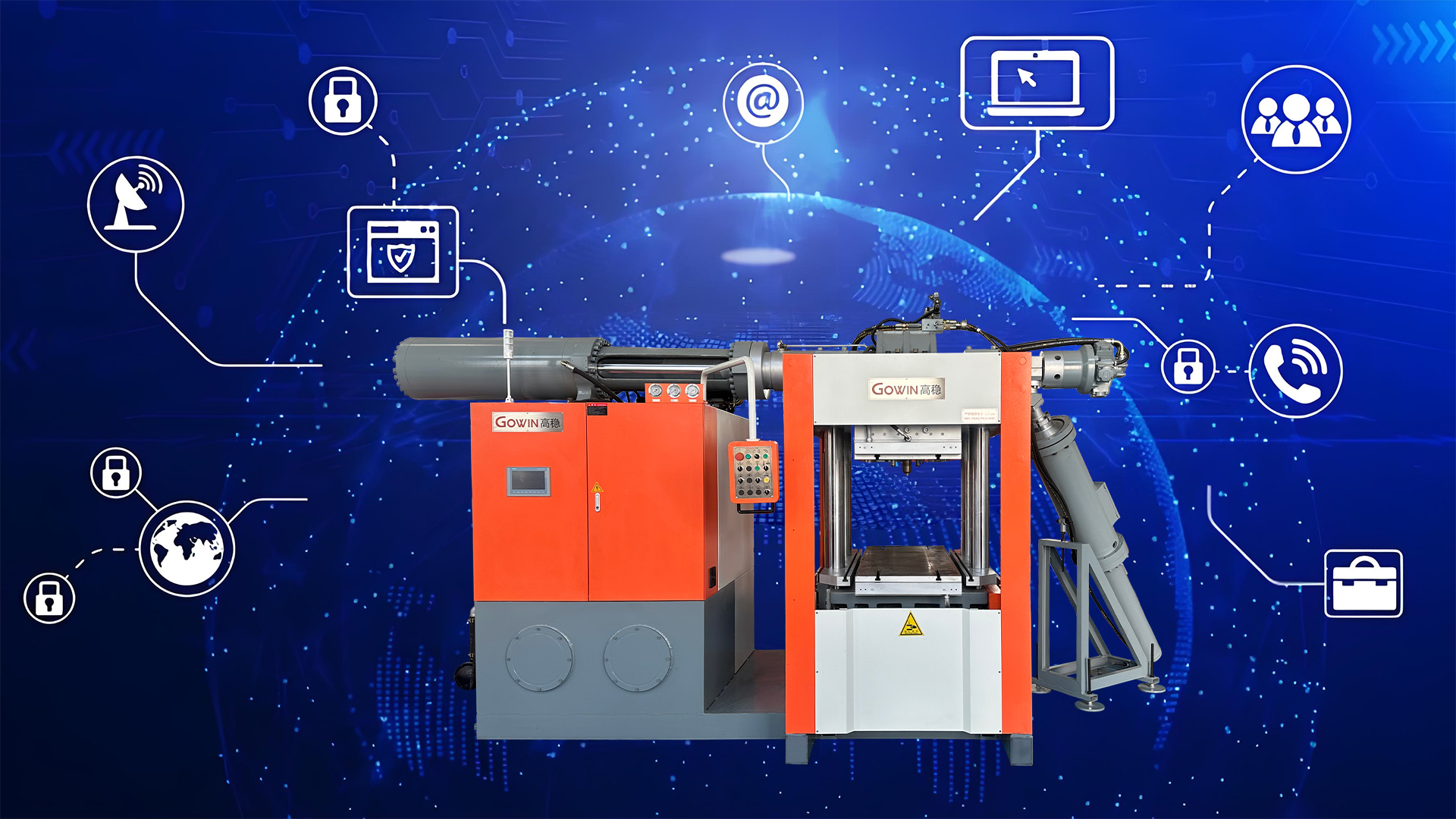

Enter GOWIN’s GW-S550L Solid Silicone Injection Machine—a technological leap designed specifically for energy-grade insulator production. Here’s why it’s redefining standards in power infrastructure:

Why Insulators Matter More Than Ever

Insulators are the unsung heroes of power grids, preventing energy loss, withstanding extreme weather, and ensuring uninterrupted electricity flow. But as grids expand to integrate renewables and handle higher voltages (up to 500kV+), the stakes are higher:

35% of grid failures stem from insulator degradation.

High-voltage insulators must endure temperatures from -40°C to 200°C and resist UV, pollution, and salt fog.

Traditional porcelain and glass insulators are increasingly replaced by silicone composite insulators—lighter, more durable, and maintenance-free. But producing them requires next-level precision.

GW-S550L: Engineered for Energy Excellence

Designed for 35kV+ suspension insulators and polymer surge arresters, the GW-S550L combines German engineering with smart manufacturing to deliver unmatched quality:

✅ Angle-Type Injection System: Ensures uniform silicone flow for zero voids or bubbles—critical for high-voltage insulation.

✅ 8,000cc Injection Volume: Produces large-scale insulators (e.g., 1.8m suspension types) in ≤3-minute cycles, 30% faster than competitors.

✅ 2000 Bar Clamping Force: Eliminates flash and burrs, achieving ±0.1mm dimensional accuracy—meeting IEC 61109 standards.

✅ Energy Recovery System: Reduces power consumption by 25%, aligning with EU Green Deal and China’s carbon neutrality goals.

Scrap rates dropped from 12% to 1.5% through AI-driven viscosity monitoring.

Production capacity doubled with rapid mold changes (<15 minutes vs. industry 60+ mins).

Annual CO₂ emissions reduced by 150 tons via energy-efficient hydraulics.

“The GW-S550L meet ISO 50001 standards while cutting costs. It’s now the core of smart factory.”

Why GOWIN Outperforms Competitors

GOWIN offers unique advantages for specialized manufacturers:

Modular Design: Customize configurations for HV insulators, cable joints, or renewable energy components.

IoT Integration: Real-time monitoring via 10-inch HMI predicts maintenance needs, slashing downtime.

Multi-Material Flexibility: Seamlessly switch between HTV silicone, EPDM, and recycled rubber to combat supply chain disruptions.

The Road Ahead: Sustainability Meets Smart Grids

With the silicone composite insulator market set to hit $2.1B by 2033 (Verified Market Reports, 2024), manufacturers need partners who prioritize:

Post time: May-17-2025